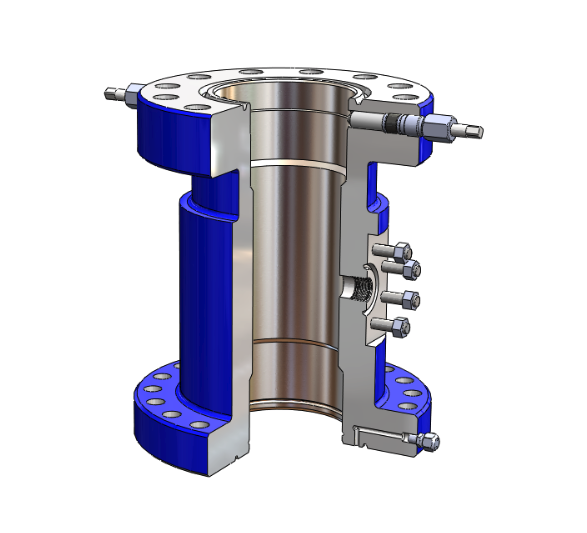

The Casing Spool is a wellhead component that provides a means to support and seal an intermediate casing string. The upper section has a straight type bowl and a 45 degree load shoulder to support the production casing string. The lower section houses a secondary seal to isolate the two casing strings and provide a means to test the wellhead seals.

- Provides a sealing point over the intermediate casing.

- Allows for pressure testing of the wellhead seals to isolate the casing strings.

- Allows for support and testing of a BOP system while drilling out for the next casing string.

- Provides a casing hanger load shoulder and bowl for hanging and sealing of the next casing string.

- The load shoulder and bowl also accommodate BOP test plugs.

- Provides two outlets for annular access and monitoring.

- Provides a means for Wear Bushing installation and retention.

- C-29 bowls available for extreme casing loads.

- Both accept C-21 and C-21-P Casing Hangers for low weight situations.

Outlets

- Threaded 2” LP (LPO)

- Threaded EUE 8rd

- Side Studded Outlets (SSO) with internal VR prep

- Extended Flanged Outlets (EFO) with internal VR prep

Bottom profile

- BG (blank), accepts a wide variety of secondary seals

- O-ring bottom, made to specific casing sizes

- P-Seal bottom, made to specific casing sizes and must be energized by plastic packing

- FS bottom (high pressure) made to specific casing size

Lock-down Pins

- ET style pins eliminate exposed lock-down pin threads

- Full set of pins to secure mandrel casing or tubing hangers (suffix “L”)

- 2 BP pins (bowl protector) to secure wear bushings while drilling (suffix “BP”)